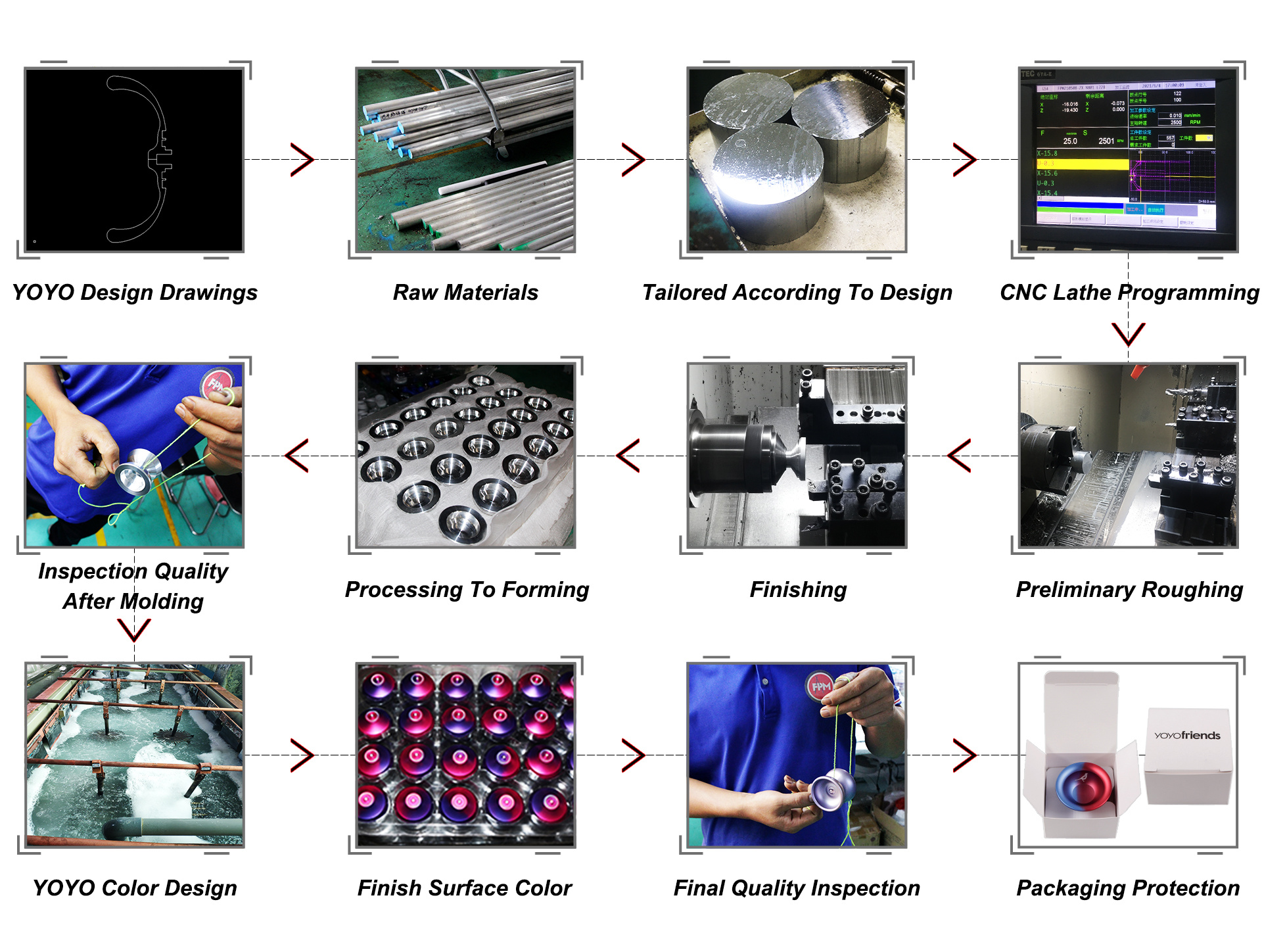

About the basic process of manufacturing yo-yo.

Hi everyone,

In 2025 April, the FPM team visited Japan to meet with some clients and friends. Since returning, we’ve been eager to share more about what we do—especially our production process and how we ensure top quality.

As many of you know, our main focus at FPM has always been quality control. Today, using our bimetal yo-yos as an example, I’ll walk you through how our products are made and inspected, step by step.

Step 1: Once we receive a customer order, we prepare the materials according to the specifications.

Step 2: Manufacturing – FPM uses a different approach from other manufacturers. To eliminate vibration caused by lack of precision, all FPM products are made in a single-piece process, regardless of material (aluminum, titanium, POM, or PC). This requires more steps and lower efficiency:

A:Two rounds of rough machining to shape the product.

B:Two rounds of precision machining to complete it.

During production, we perform and record hourly inspections.

A core principle at FPM: we never alter a customer’s design. To preserve originality, we invest heavily in product tuning. In one case, it took 98 raw pieces and a full week to successfully fine-tune a single model.

Step 3: All products are sent to the Quality Department for visual inspection, with a 100% inspection rate.

To improve quality, we established a dedicated Quality Department in 2024 and increased the inspection rate from 20% to 100%. We will categorize the inspected products into three types: Passed (green label), Rework needed (yellow label), and Scrap (red label).. The Production Department uses this data to analyze and improve manufacturing issues.

This added quality control step significantly impacts efficiency—overall production speed has dropped by over 50%. But we believe it’s worth it. If we must choose, we choose quality.

Step 4: Sandblasting

Step 5: Quality Inspection

To ensure there are no defects on the sandblasted surface, we conduct a 100% visual inspection of the product.

Step 6: Anodizing

As many know, starting in 2024, FPM has employed dedicated anodizing technicians to guarantee the uniqueness of our products.

Step 7: Anodizing Quality Inspection

After anodizing is completed, the product returns to the quality department for another 100% surface inspection.

Step 8: Ring Production

Ring production begins only after the main body has been anodized, to ensure consistent alignment and fit during assembly.

Step 9: Ring Inspection

Once the rings are completed, they are sent to the quality department for a full 100% visual inspection.

Step 10: Ring Sandblasting or Electroplating

After inspection, the rings undergo either sandblasting or electroplating, depending on the design requirements.

Step 11: After sandblasting or electroplating, we carry out 100% visual inspection of the rings.

Step 12: Assembly — To improve efficiency, we have 7 dedicated assembly workers.

Step 13: Post-assembly check — Once assembled, each yoyo is inspected again by our assembly supervisor to ensure performance consistency. Yes, 100% checked.

Step 14: After assembly, the product returns to the Quality Department for a final visual inspection 100%.

Step 16: Laser engraving test.

Step 17: Packaging.

As you can see, since 2024, full-process inspection has become a top priority at FPM. This has significantly slowed down our overall efficiency. We now operate 14 machines and employ 40 full-time workers — all focused solely on making yoyos. The cost is high, and yes, it hurts.

Many friends have asked me: “it’s just a yoyo, a toy. Do you really have to set such strict standards?”

I’ve asked myself the same question more than once. But I can’t give up — because deep down, I believe: A good yoyo has a soul. It speaks. It shows our customers what FPM stands for — quality they can trust.

Thank you all for listening to my story. We always prioritize product quality, now and in the future, because when you choose us, you choose FPM.

Feel free to share any thoughts or questions in the comments below!

If you have any questions, you can consult us, we will provide you with meticulous help!